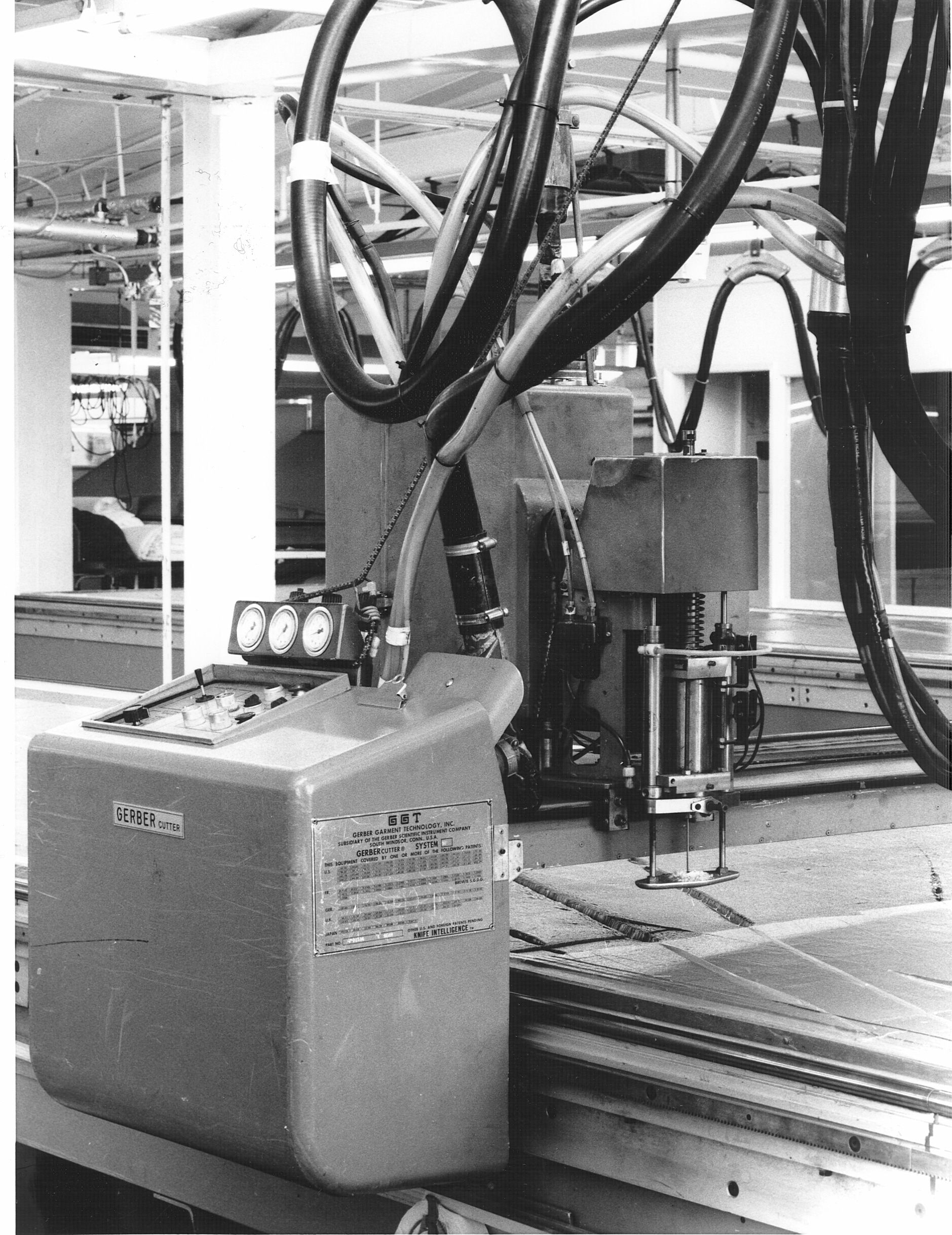

In June 1975 a Camsco Markamatic System and Gerber System 90 Computer Driven Cloth Cutter was installed in the cutting room at the Pleasant Hill factory. A larger Gerber 91 machine was installed in January 1979. These allowed for automatic stock cutting. The cutting table consisted of nylon fibres approximately 3 inches deep to allow the cutting blade to penetrate. The lay was covered by plastic to allow the vacuum to compress the lay and hold it firm for cutting. The smaller Gerber cutter was used for small lays and trimmings, while the larger cutter basically cut all plain stock garments.

The fabric was layed up by a Bullmer laying up machine, operated by one person with an average of 3-4 bolts per lay. These were conveyed to the cutting table by a special transfer table and removed by air flotation.

"The automatic bullmer laying up machine prepares the fabric in lay form for the Gerber cutting machine. To transfer the laid up fabric to the cutting surface we use a system of air floatation, this system makes it possible to move very heavy fabrics form one table to another with little effort. The middle table moves along over to the cutting surface, the fabric is left behind ready for the next step. The fabric is covered with a layer of plastic film, then air is drawn down to create a vacuum, this makes the fabric very firm so that it won’t move when the cutting blade is doing its work. The cutting surface is brush like nylon fibres 7cm deep; this allows the cutting blade to penetrate right through the fabric. The average cutting time for a lay is 23 mins. The average yield would be 250 trousers or 400 shorts or 400 shirts."

Information supplied by Robert Lanchbery who worked at Fletcher’s for 33 years from 1965-1998. Robert worked in pattern making, store specials, pleating and fabric inspection as well a tour guide for the factory and gardens.